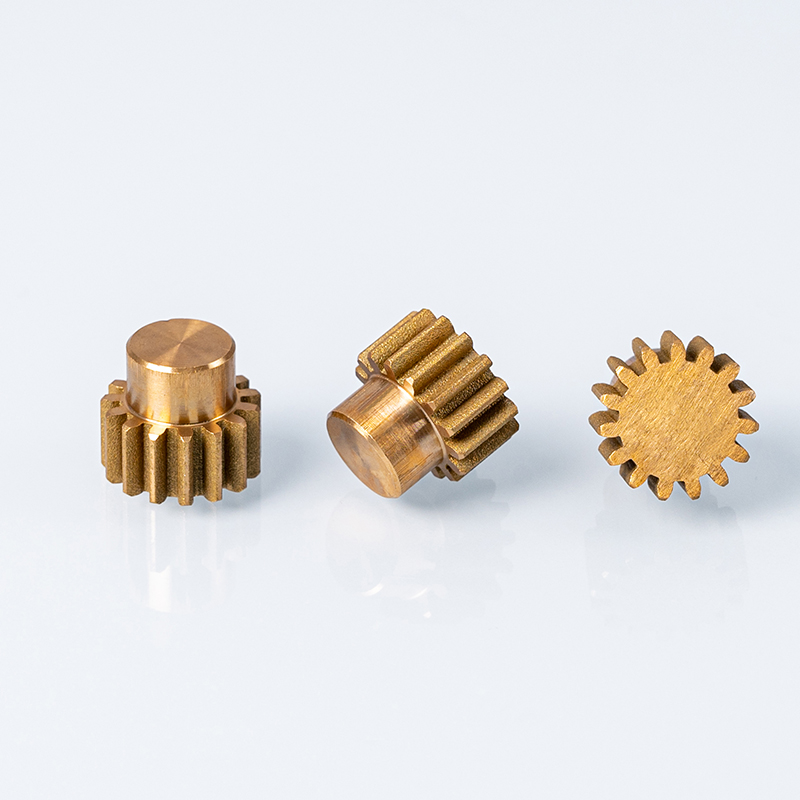

CNC machining nyob rau hauv tooj liab qhov chaw rau kev kho mob

Specification ntawm CNC machining qhov chaw nrog tooj liab khoom

Tooj liab kuj yog nonmagnetic thiab tsis-sparking, ua rau nws haum rau siv nyob rau hauv cov khoom kho mob uas raug rau hluav taws xob tam sim no los yog high-voltage teb. Tooj liab kuj yog corrosion-resistant, uas ua rau nws xaiv zoo rau cov khoom siv kho mob uas raug dej los yog lwm yam kua. CNC machining nyob rau hauv tooj liab tso cai rau zus tau tej cov complex, intricate qhov chaw nrog ib tug high degree ntawm raug thiab precision. Cov khoom siv tooj liab tuaj yeem ua tau raws li cov lus qhia tshwj xeeb thiab kev ua siab ntev, ua kom cov khoom siv kho mob muaj kev nyab xeeb thiab siv tau zoo.

1. Khoom siv tooj liab: C110 (99.9% tooj liab)

2. Txheej Txheem: CNC Machining

3. Kev kam rau siab: +/- 0.01mm

4. Finish: Ntuj 5. Daim Ntawv Thov: Siv hauv electronics, hluav taws xob, teeb pom kev zoo thiab lwm yam lag luam.

Qhov zoo ntawm CNC machining tooj liab

CNC machining tooj liab muaj ntau yam zoo, xws li siab precision thiab raug, zoo heev zog-rau-qhov hnyav piv, zoo thermal thiab hluav taws xob conductivity, muaj zog corrosion kuj piv rau lwm yam hlau, qhov ntev stability nyob rau hauv ib tug dav kub ntau yam, txo lub sij hawm lub tshuab vim nws malleability thiab yooj yim ntawm machinability.

1. Superior zog thiab durability - tooj liab yog ib qho khoom siv ruaj khov heev thiab muaj peev xwm tiv taus qhov kub thiab txias, siab thiab hnav. Qhov no ua rau nws yog ib qho kev xaiv zoo heev rau CNC machining daim ntaub ntawv, raws li nws yuav siv tau nyob rau hauv ib tug ntau yam ntawm daim ntawv thov thiab muaj peev xwm tiv taus cov rigors ntawm repetitive, high-precision machining ua hauj lwm.

2. Cov thermal conductivity zoo heev - tooj liab zoo thermal conductivity ua rau nws zoo tagnrho rau CNC machining daim ntaub ntawv uas yuav tsum tau precision txiav thiab drilling ua hauj lwm. Qhov no ua kom ntseeg tau tias cov khoom tiav yuav muaj qib siab tshaj plaws ntawm qhov tseeb thiab qhov tseeb.

3. Cov khoom siv hluav taws xob siab - Qhov no ua rau tooj liab yog cov khoom siv zoo tshaj plaws rau CNC machining kev ua haujlwm uas yuav tsum tau siv hluav taws xob thaiv lossis cov khoom siv.

4. Tus nqi zoo - tooj liab feem ntau tsis tshua kim dua li lwm cov hlau, ua rau nws yog qhov kev xaiv zoo tshaj plaws rau CNC machining tej yaam num uas xav tau ntau qhov chaw lossis cov khoom siv.

5. Yooj yim rau kev ua haujlwm nrog - tooj liab yog ib qho khoom siv yooj yim rau kev ua haujlwm nrog, tso cai rau kev tsim khoom sai dua thiab raug ntau dua.

Yuav ua li cas tooj liab hauv CNC machining qhov chaw

CNC machining tooj liab qhov chaw suav nrog kev siv cov cuab yeej txiav cov cuab yeej xws li cov mills kawg kom tshem tawm cov khoom ntawm lub workpiece raws li txoj hauv kev. Lub programming rau CNC machining yog ua los ntawm kev siv computer-aided tsim (CAD) software thiab tom qab ntawd xa mus rau lub tshuab ntawm G code, uas tso cai rau nws ua txhua qhov kev txav mus los. Cov tooj liab tuaj yeem raug laum, milled lossis tig nyob ntawm daim ntawv thov. Cov kua hlau ua haujlwm kuj tseem siv tau thaum lub sijhawm CNC machining txheej txheem, tshwj xeeb tshaj yog thaum cuam tshuam nrog cov hlau nyuaj xws li tooj liab uas yuav tsum tau lubrication ntxiv.

CNC machining tooj liab qhov chaw yog ib tug machining txheej txheem ntawm kev siv lub computer zauv tswj (CNC) cov cav tov los tsim cov khoom tooj liab. Copper yog siv nyob rau hauv ntau yam ntawm CNC daim ntaub ntawv xws li prototyping, pwm, fixtures, thiab kawg siv qhov chaw.

CNC machining tooj liab yuav tsum tau siv cov software tshwj xeeb thiab CNC tshuab uas tau nruab nrog cov cuab yeej tsim nyog kom raug txiav thiab tsim cov khoom. Cov txheej txheem pib los ntawm kev tsim tus qauv 3D ntawm qhov xav tau hauv CAD program. Tus qauv 3D yog tom qab ntawd hloov mus rau hauv cov cuab yeej cuab tam, uas yog ib txheej ntawm cov lus qhia uas ua haujlwm rau CNC tshuab los tsim cov duab uas xav tau.

Lub tshuab CNC yog tom qab ntawd thauj khoom nrog cov cuab yeej tsim nyog, xws li qhov kawg mills thiab laum cov khoom, thiab cov khoom yuav raug thauj mus rau hauv lub tshuab. Cov khoom yog tom qab ntawd machined raws li lub programmed txoj kev thiab cov yam xav tau yog tsim. Tom qab cov txheej txheem machining tiav, ib feem raug tshuaj xyuas kom nws ua tau raws li cov lus qhia tshwj xeeb. Yog tias tsim nyog, ib feem yog ua tiav nrog ntau yam txheej txheem tom qab ua haujlwm xws li buffing thiab polishing.

Dab tsi CNC machining qhov chaw tuaj yeem siv rau tooj liab

CNC machining tooj liab qhov chaw tuaj yeem siv rau ntau yam kev siv, suav nrog cov khoom siv hluav taws xob thiab cov khoom sib txuas, cov khoom siv hluav taws xob siab, cov khoom siv dav hlau, cov khoom siv kho mob, cov tshuab sib dhos thiab lwm yam. Copper CNC machined qhov chaw feem ntau plated nrog lwm yam hlau los txhim kho conductivity lossis hnav tsis kam.

CNC machining tooj liab qhov chaw tuaj yeem siv rau ntau yam kev siv, suav nrog cov khoom siv hluav taws xob, lub cev muaj zog, cov khoom siv hluav taws xob, cov khoom siv hluav taws xob, cov khoom siv hluav taws xob, thiab cov khoom siv zoo nkauj. Cov tooj liab yog qhov zoo tagnrho rau CNC machining vim nws cov hluav taws xob siab thiab thermal conductivity, thiab nws zoo heev corrosion kuj. CNC machining tooj liab kuj tuaj yeem siv los tsim cov duab sib txawv thiab qhov chaw nrog qhov ua siab ntev.

Yam kev kho saum npoo zoo li cas rau CNC machining qhov chaw ntawm tooj liab

Qhov zoo tshaj plaws kev kho deg rau CNC machining tooj liab qhov chaw yog anodizing. Anodizing yog ib qho txheej txheem uas cuam tshuam nrog electro chemically kho cov hlau thiab tsim cov oxide txheej ntawm cov khoom uas ua rau kom hnav tsis kam thiab tiv thaiv corrosion. Nws kuj tseem siv tau los muab cov khoom siv zoo nkauj xws li cov xim ci, matte tiav lossis glowing tones.

Copper alloys feem ntau yog kho nrog electroless nickel plating, anodizing, thiab passivation los tiv thaiv nto ntawm corrosion thiab hnav. Cov txheej txheem no kuj yog siv los txhim kho kev zoo nkauj ntawm ib feem.

Daim ntawv thov:

3C kev lag luam, teeb pom kev zoo, khoom siv hluav taws xob, tsheb qhov chaw, rooj tog zaum, cov cuab yeej hluav taws xob, cov khoom siv kho mob, cov cuab yeej ntse automation, lwm yam hlau casting qhov chaw.