Dab tsi ntawm cov khoom tshwj xeeb yuav siv rau hauv cov roj & Gas CNC machined qhov chaw?

CNC machined qhov chaw siv nyob rau hauv cov roj thiab roj kev lag luam yuav tsum tau tshwj xeeb cov ntaub ntawv uas muaj peev xwm tiv taus high-pressure, high-temperature, thiab corrosive ib puag ncig.Nov yog qee cov ntaub ntawv tshwj xeeb uas feem ntau siv hauv cov roj thiab roj CNC machined qhov chaw nrog rau lawv cov ntaub ntawv code:

Thaum xaiv cov khoom siv rau roj thiab roj CNC machined qhov chaw, nws yog ib qho tseem ceeb uas yuav tau xav txog cov kev thov tshwj xeeb, xws li siab, kub, thiab corrosion kuj.Cov khoom siv yuav tsum tau ua tib zoo xaiv los xyuas kom meej tias cov khoom tuaj yeem tiv taus qhov kev cia siab ntawm kev thauj khoom thiab ib puag ncig thiab muab kev ua tau zoo tshaj qhov kev pab cuam lub neej.

| Roj Khoom Siv | Roj Khoom Code |

| Nickel Alloy | Hnub nyoog 925, INCONEL 718 (120,125,150,160 KSI), NITRONIC 50HS, MONEL K500 |

| Stainless hlau | 9CR, 13CR, SUPER 13CR, 410SSTANN, 15-5PH H1025,17-4PH(H900/H1025/H1075/H1150) |

| Tsis-magnetic Stainless hlau | 15-15LC, P530, Datalloy 2 |

| Hlau alloy | S-7,8620, SAE 5210,4140,4145H MOD, 4330V, 4340 |

| Copper Alloy | AMPC 45, TUGHMET, BRASS C36000, BRASS C26000, BeCu C17200, C17300 |

| Titanium alloy | CP Titanium GR.4, Ti-6AI-4V, |

| Cobalt-base Alloys | STELLITE 6,MP35N |

Dab tsi ntawm cov khoom tshwj xeeb yuav siv rau hauv cov roj & Gas CNC machined qhov chaw?

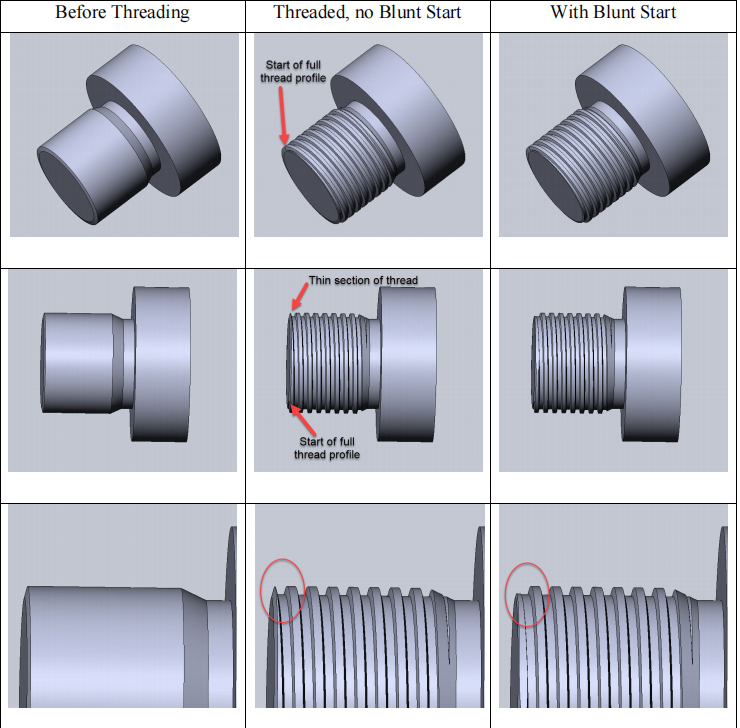

Cov xov tshwj xeeb siv hauv cov roj thiab roj CNC machined qhov chaw yuav tsum tau tsim kom tau raws li cov kev xav tau ntawm daim ntawv thov, xws li kev kub siab, kub kub, thiab hnyav ib puag ncig.Cov xov uas siv ntau tshaj plaws hauv kev lag luam roj thiab roj muaj xws li:

Rov tsim cov lus teb

Thaum xaiv ib lub xov rau roj thiab roj CNC machined qhov chaw, nws yog ib qho tseem ceeb uas yuav tau xav txog cov kev thov tshwj xeeb thiab xaiv cov xov uas tuaj yeem tiv taus qhov kev cia siab thiab ib puag ncig.Nws tseem yog ib qho tseem ceeb kom ntseeg tau tias cov xov yog tsim los rau cov qauv tsim nyog thiab cov lus qhia tshwj xeeb kom ntseeg tau tias muaj kev sib raug zoo nrog lwm cov khoom hauv lub cev.

Nov yog qee qhov tshwj xeeb xov rau siv:

| Roj Xov Hom | Roj Tshwj Xeeb Nto Kho |

| UNRC Xov Xwm | Nqus electron beam welding |

| UNRF Xov | Nplaim Sprayed (HOVF) nickel tungsten carbide |

| TC Xov | tooj liab plating |

| API Xov | HVAF (High Velocity Air Fuel) |

| Spiralock Xov | HVOF (High Velocity Oxy-Fuel) |

| Square Xov |

|

| Buttress Xov |

|

| Tshwj xeeb Buttress Xov |

|

| OTIS SLB Xov |

|

| NPT Xov |

|

| Rp(PS) Xov |

|

| RC (PT) xov |

Dab tsi ntawm kev kho deg tshwj xeeb yuav siv rau hauv cov roj & Gas CNC machined qhov chaw?

Kev kho deg ntawm CNC machined qhov chaw yog ib qho tseem ceeb ntawm kev ua kom lawv cov kev ua haujlwm, durability, thiab ntev nyob rau hauv cov xwm txheej hnyav ntawm kev lag luam roj thiab roj.Muaj ntau ntau hom kev kho deg uas feem ntau siv hauv kev lag luam no, suav nrog:

Nws yog ib qho tseem ceeb uas yuav tau xaiv qhov kev kho saum npoo uas tsim nyog raws li daim ntawv thov tshwj xeeb thiab kev ua haujlwm ntawm CNC machined qhov chaw hauv kev lag luam roj thiab roj.Qhov no yuav ua kom ntseeg tau tias cov khoom muaj peev xwm tiv taus cov xwm txheej hnyav thiab ua lawv txoj haujlwm xav tau zoo thiab ua tau zoo.

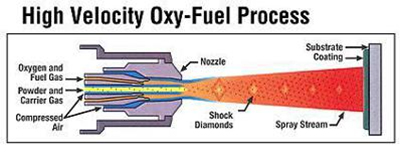

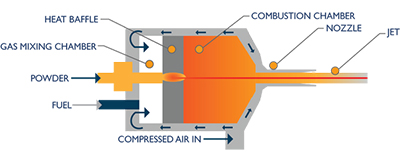

HVAF (High-Velocity Air Fuel) & HVOF (High-Velocity Oxygen Roj)

HVAF (High-Velocity Air Fuel) thiab HVOF (High-Velocity Oxygen Fuel) yog ob txheej txheej txheej txheej txheej txheej txheej txheem uas feem ntau siv hauv kev lag luam roj thiab roj.Cov tswv yim no suav nrog cua sov cov khoom siv hmoov thiab ua kom nws nrawm nrawm ua ntej tso nws mus rau saum npoo ntawm cov tshuab ua haujlwm.Lub siab ntev ntawm cov hmoov av ua rau ntom ntom thiab nruj nreem

HVOF

HVAF

HVAF thiab HVOF txheej tuaj yeem siv los txhim kho kev ua haujlwm thiab kev ua neej nyob ntawm CNC machined qhov chaw hauv kev lag luam roj thiab roj.Qee qhov txiaj ntsig ntawm HVAF thiab HVOF txheej muaj xws li:

1.Corrosion Resistance: HVAF thiab HVOF txheej tuaj yeem muab kev tiv thaiv corrosion zoo rau cov khoom siv hauv cov chaw hnyav ntawm kev lag luam roj thiab roj.Cov txheej txheem no tuaj yeem tiv thaiv qhov chaw ntawm qhov chaw los ntawm kev raug cov tshuaj corrosive, kub siab, thiab siab.

2.Hnav Resistance: HVAF thiab HVOF txheej tuaj yeem muab kev hnav zoo rau cov khoom siv hauv kev lag luam roj thiab roj.Cov txheej txheem no tuaj yeem tiv thaiv qhov chaw ntawm qhov chaw los ntawm kev hnav vim kev puas tsuaj, cuam tshuam, thiab yaig.

3.Txhim kho Lubricity: HVAF thiab HVOF txheej tuaj yeem txhim kho lubricity ntawm cov khoom siv hauv kev lag luam roj thiab roj.Cov txheej txheem no tuaj yeem txo qhov kev sib txhuam ntawm cov khoom txav, uas tuaj yeem ua rau kev txhim kho kev ua haujlwm thiab txo qis hnav.

4.Thermal Resistance: HVAF thiab HVOF txheej tuaj yeem muab cov thermal ua haujlwm zoo rau cov khoom siv hauv kev lag luam roj thiab roj.Cov txheej txheej no tuaj yeem tiv thaiv qhov chaw los ntawm thermal shock thiab thermal cycling, uas tuaj yeem ua rau tawg thiab tsis ua haujlwm.

5.Hauv cov ntsiab lus, HVAF thiab HVOF txheej txheej yog cov txheej txheem txheej txheej txheej txheej uas tuaj yeem muab kev tiv thaiv zoo rau CNC machined qhov chaw siv hauv kev lag luam roj thiab roj.Cov txheej txheem no tuaj yeem txhim kho qhov kev ua tau zoo, ua haujlwm ntev, thiab lub neej ntev ntawm cov khoom, ua rau kev txhim kho kev ua haujlwm zoo thiab txo nqi txij nkawm.