Dab tsi yog tuag casting

Tuag casting yog txheej txheem tsim khoom siv los tsim cov khoom hlau nrog qhov tseeb qhov tseeb thiab qhov chaw tiav. Nws suav nrog yuam cov hlau molten rau hauv pwm kab noj hniav nyob rau hauv siab. Lub pwm kab noj hniav yog tsim los ntawm ob hardened steel tuag uas yog machined rau hauv cov duab uas xav tau.

Cov txheej txheem pib nrog melting ntawm cov hlau, feem ntau yog txhuas, zinc, los yog magnesium, nyob rau hauv lub cub tawg. Tom qab ntawd cov hlau molten yog txhaj rau hauv pwm ntawm kev kub siab siv hydraulic xovxwm. Cov hlau solidifies sai sai nyob rau hauv lub pwm, thiab ob halves ntawm pwm yog qhib kom tso cov tiav ib feem.

Tuag casting yog dav siv los tsim cov khoom uas muaj cov duab thiab cov phab ntsa nyias, xws li cov cav cav, cov tsev sib kis, thiab ntau yam khoom siv hauv tsheb thiab aerospace. Cov txheej txheem kuj tseem nrov hauv kev tsim cov khoom siv, xws li cov khoom ua si, chav ua noj, thiab khoom siv hluav taws xob.

Siab Tuag Casting

Tuag casting yog txheej txheem tshwj xeeb uas tau tsim ntau dua nyob rau hauv lub xyoo pua 20th. Cov txheej txheem yooj yim muaj xws li: molten hlau yog nchuav / txhaj rau hauv cov pwm hlau thiab dhau ntawm qhov nrawm nrawm, tsis tu ncua thiab ua kom muaj zog (hauv siab tuag casting) thiab txias cov hlau molten solidifies los tsim cov khoom casting. Feem ntau, cov txheej txheem nws tus kheej tsuas yog siv ob peb vib nas this thiab yog txoj hauv kev nrawm ntawm kev tsim cov khoom hlau los ntawm cov khoom siv raw. Tuag casting yog haum rau cov ntaub ntawv xws li tin, lead, zinc, aluminium, magnesium rau tooj liab alloys thiab txawm hlau alloys xws li stainless hlau. Lub ntsiab alloys siv niaj hnub no hauv siab tuag casting yog aluminium, zinc thiab magnesium. Los ntawm cov tshuab tuag cam thaum ntxov uas taw qhia cov cuab yeej tuag hauv txoj kab ntsug mus rau tam sim no tus qauv ntawm kab rov tav orientation thiab kev ua haujlwm, plaub khi bar tensioning thiab tag nrho lub computer tswj cov txheej txheem cov txheej txheem tau nce thoob plaws hauv lub xyoo.

Kev lag luam tau loj hlob mus rau hauv lub tshuab tsim thoob ntiaj teb, ua cov khoom siv rau ntau yam kev siv, ntau yam yuav ncav cuag los ntawm tus kheej raws li cov khoom siv ntawm kev tuag castings yog ntau haiv neeg.

Cov txiaj ntsig ntawm lub siab tuag casting

Qee qhov txiaj ntsig ntawm kev kub siab tuag casting:

• Cov txheej txheem tsim nyog rau cov khoom ntim siab.

• Tsim kom muaj kev sib raug zoo castings sai sai piv rau lwm cov txheej txheem hlau (xws li machining).

• Cov khoom siv muaj zog siab ua tau raws li qhov xwm txheej cam khwb cia (raws li kev tsim qauv).

• Dimensional repeatability.

• Cov phab ntsa nyias nyias ua tau (xws li 1-2.5mm).

• Zoo linear kam rau ua (piv txwv li. 2mm/m).

• Zoo nto tiav (piv txwv li. 0.5-3 µm).

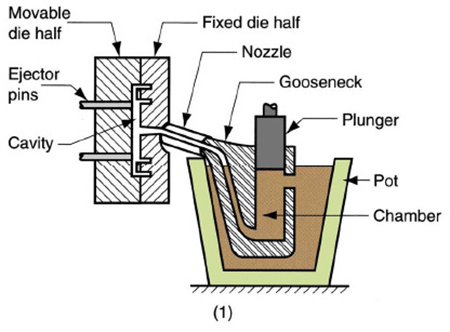

Vim tias qhov no "kaw" hlau yaj / txhaj tshuaj thiab cov tshuab hluav taws xob tsawg tsawg kub chamber tuag casting tuaj yeem muab kev lag luam zoo dua rau kev tsim khoom. Zinc hlau alloy feem ntau yog siv nyob rau hauv kub chamber siab tuag casting uas muaj ib tug ncaj tsawg melting point uas muaj kev pab ntxiv rau cov tsis tshua muaj hnav ntawm cov cav tov (lub lauj kaub, gooseneck, lub tes tsho, plunger, nozzle) thiab kuj tsis tshua muaj hnav ntawm cov cuab yeej tuag (lub neej ntev dua piv rau txhuas tuag casting cov cuab yeej - raug rau casting zoo txais).

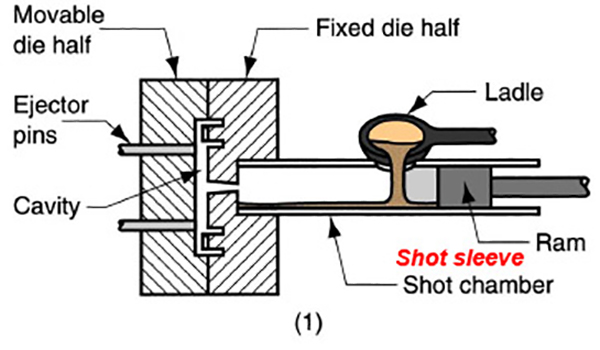

Cov tshuab txias chamber yog tsim rau txhuas tuag casting, qhov chaw ntawm lub tshuab (shot tes tsho, plunger tip) tuaj yeem hloov lub sijhawm, lub tes tsho tuaj yeem ua hlau kho kom lawv cov kav ntev. Aluminium alloy yog melted nyob rau hauv ceramic crucible vim aluminium qhov txheeb ze melting point thiab yuav tsum tau txo qhov kev pheej hmoo ntawm cov hlau pickup uas yog ib qho kev pheej hmoo nyob rau hauv ferrous crucibles. Vim hais tias txhuas yog ib tug kuj lub teeb hlau alloy nws them taus casting ntawm loj thiab hnyav tuag castings los yog qhov twg muaj zog thiab lightness nyob rau hauv tuag castings yuav tsum tau.