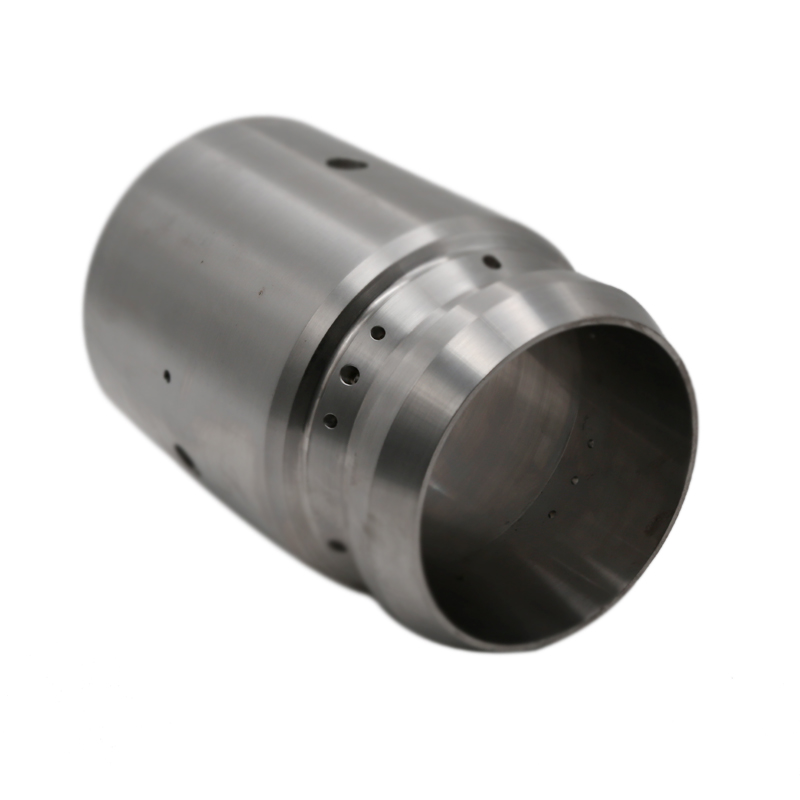

Inconel CNC siab precision machining qhov chaw

Cov ntaub ntawv muaj:

Polycarbonate yog cov thermoplastic polymer tsim los ntawm carbonate pawg txuas ua ke los tsim cov saw ntev molecule. Nws yog lub teeb yuag, ruaj khov yas nrog zoo heev optical, thermal thiab hluav taws xob khoom. Nws muaj kev tiv thaiv zoo heev rau kev cuam tshuam, kub thiab tshuaj lom neeg, thiab siv ntau yam kev siv, los ntawm cov khoom siv kho mob mus rau cov khoom siv tsheb. Nws muaj nyob rau hauv ntau qib, cov ntaub ntawv thiab xim, thiab feem ntau yog muag nyob rau hauv nplooj ntawv, rods thiab raj.

Specification ntawm Inconel Hlau

1, Cov Khoom Siv Tshuaj: Inconel alloys feem ntau muaj npib tsib xee, chromium, hlau, thiab lwm yam khoom xws li molybdenum, cobalt, thiab titanium.

2, Mechanical Properties: Inconel alloys muaj lub zog siab, zoo heev ductility, thiab zoo toughness ntawm ob qho tib si ambient thiab siab kub.

3, Corrosion Resistance: Inconel alloys muaj kev tiv thaiv zoo heev rau ntau qhov chaw, suav nrog oxidizing thiab txo cov kua qaub, dej ntsev, thiab cov roj kub kub.

4 、 Kev Ua Haujlwm Kub Kub: Inconel alloys tuaj yeem tswj hwm lawv cov khoom siv dag zog thiab kev tiv thaiv corrosion ntawm qhov kub siab txog 2000 ° F (1093 ° C).

5, Weldability: Inconel alloys yog weldable siv cov txheej txheem vuam, tab sis qee qib yuav xav tau preheating thiab tom qab vuam kev kho cua sov kom tswj tau lawv cov khoom.

6, Qib: Muaj ntau qib ntawm Inconel alloys muaj, suav nrog Inconel 600, Inconel 625, Inconel 718, thiab Inconel X-750, txhua tus muaj cov tshuaj lom neeg tshwj xeeb thiab cov khoom.

Tuam txhab Profile

LAIRUN tau tsim muaj nyob rau hauv 2013, Peb yog ib tug nruab nrab-qhov loj me CNC machining qhov chaw chaw tsim tshuaj paus, mob siab rau muab high-zoo precision qhov chaw rau ntau yam industries. Peb muaj txog 80 tus neeg ua haujlwm nrog ntau xyoo dhau los thiab pab pawg kws tshaj lij, peb muaj cov kws tshaj lij thiab cov cuab yeej siv niaj hnub tsim nyog los tsim cov khoom sib txuam nrog qhov tseeb tshwj xeeb thiab sib xws.