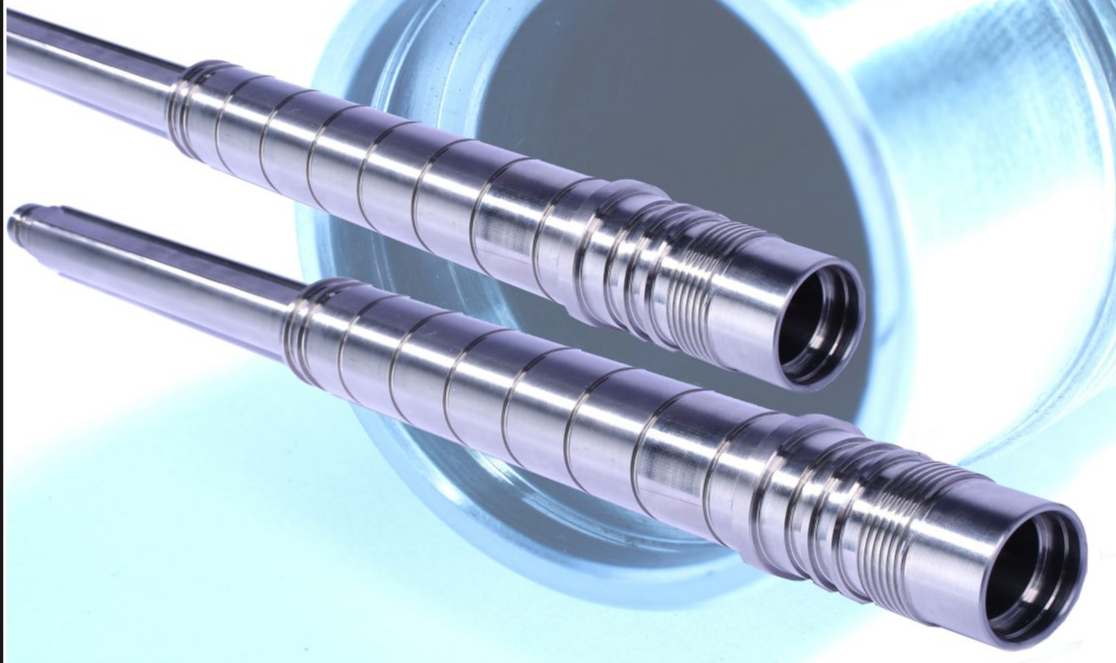

Ntawm LAIRUN, peb txaus siab rau peb lub peev xwm ua tau zoo, tshwj xeeb tshaj yog thaum ua haujlwm nrog cov ntaub ntawv ua tau zoo xws li Inconel alloy.Inconel alloysmuaj npe nrov rau lawv qhov tshwj xeeb kub-kub lub zog, corrosion kuj, thiab durability, ua rau lawv zoo tagnrho rau ntau yam kev thov nyob rau hauv ntau yam lag luam.

Peb cov kev paub dhau los thiab cov thev naus laus zis siab heev pab kom peb xa cov kev pabcuam zoo tshaj plaws rau ntau yam tseem ceeb ntawm Inconel alloys:

● Inconel 625:Dav siv nyob rau hauv cov roj thiab roj, aerospace, thiab tshuaj industries, Inconel 625 paub txog nws zoo heev corrosion kuj thiab oxidation tsis kam, ua rau nws yog ib tug zoo xaiv rau ib puag ncig hnyav.

● Inconel 718:Cov hlau no nquag siv hauv aerospace thiab roj kev lag luam vim nws lub zog siab thiab zoo weldability. Inconel 718 yog qhov tseem ceeb rau cov khoom siv uas xav tau lub zog siab thiab thermal stability.

● Inconel 600:Feem ntau pom muaj nyob rau hauv aerospace thiab tshuaj industries, Inconel 600 muaj qhov kub thiab txias zog thiab tsis kam mus corrosion, ua rau nws haum rau ntau yam kev thov.

● Inconel 690:Feem ntau siv nyob rau hauv kev lag luam tshuaj, Inconel 690 excels nyob rau hauv high-temperature corrosive ib puag ncig, muab kev ntseeg tau zoo nyob rau hauv huab mob.

Nov yog qhov ua rau peb sib nrug hauv qhov tshwj xeeb ntawm Inconel alloy machining:

1. Advanced Machining Equipment

Peb siv lub xeev-of-the-art CNC machining chaw, precision sib tsoo cov cav tov, thiab high-performance EDM cov cav tov kom tau raws li qhov yuav tsum tau nruj me ntsis ntawm Inconel alloy machining. Peb cov cuab yeej siv tau tsim los daws qhov nyuaj ntawm kev ua haujlwm nrog cov khoom siv siab heev.

2. Pab neeg txawj Engineering

Peb pab pawg kws paub txog engineers muaj kev nkag siab tob txog Inconel alloys thiab lawv cov khoom tshwj xeeb. Lawv cov kws tshaj lij tso cai rau peb los daws cov teeb meem nyuaj machining thiab xa cov khoom muaj tseeb rau ntau yam kev lag luam.

3. Kev Tswj Xyuas Zoo

Peb ua raws li kev tswj hwm nruj nruj los saib xyuas txhua theem ntawm cov txheej txheem machining. Los ntawm kev xaiv cov ntaub ntawv raw mus rau qhov kawg kev soj ntsuam, peb xyuas kom meej tias peb cov khoom ua raws li cov qauv siab tshaj plaws.

4. Kev daws teeb meem

Peb muab cov kev daws teeb meem tsim kho kom tau raws li cov kev xav tau tshwj xeeb ntawm peb cov neeg siv khoom. Txawm hais tias ntsib qhov kev sib tw tsim tshwj xeeb lossis kev xav tau ntawm engineering, peb ua haujlwm ze nrog cov neeg siv khoom los muab cov kev daws teeb meem zoo thiab tshiab.

Peb qhov kev mob siab rau kev ua tau zoo hauv Inconel alloy machining tau ua rau peb paub txog kev xa cov khoom txhim khu kev qha thiab zoo. Peb tos ntsoov yuav txuas ntxiv peb txoj kev siv zog thiab tshawb nrhiav cov hauv kev tshiab rau kev sib koom tes.

Hu rau peb kom paub ntau ntxiv txog peb cov kev pabcuam Inconel alloy machining thiab peb tuaj yeem pab txhawb koj li cas ntxiv.

Post lub sij hawm: Lub Xya hli ntuj-10-2024