Muaj ntau qhov kev kho saum npoo uas tuaj yeem siv rau CNC machined aluminium qhov chaw. Hom kev kho mob siv yuav nyob ntawm seb qhov kev xav tau tshwj xeeb ntawm ntu thiab qhov xav tau ua tiav. Nov yog qee qhov kev kho saum npoo rau CNC machined aluminium qhov chaw:

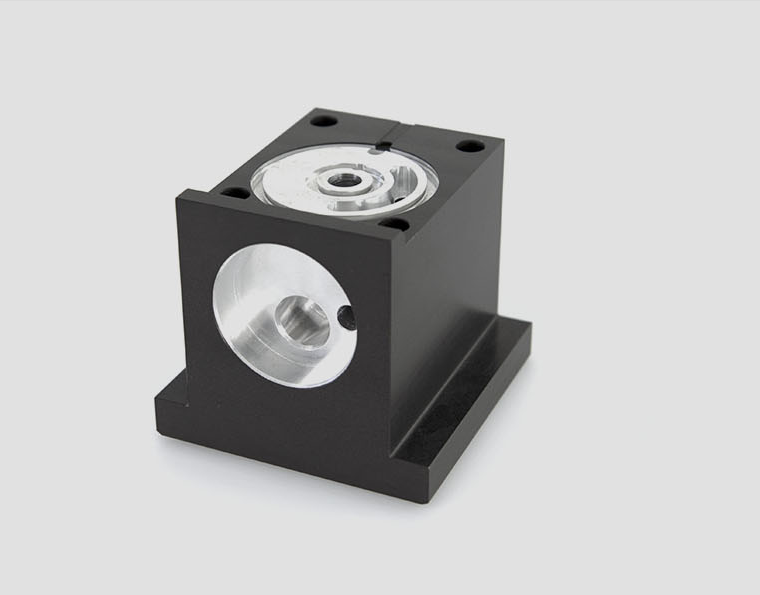

1. Anodizing / Hard anodized

Qhov no yog ib txoj kev uas ib txheej oxide yog zus nyob rau saum npoo ntawm txhuas. Anodizing tuaj yeem muab qhov ruaj khov, corrosion-resistant tag uas tuaj yeem dyed rau ntau yam xim.Yuav ua kom pom tseeb, dub, liab, xiav, ntshav, daj lossis xim uas koj xav tau raws li koj tus qauv tsim.

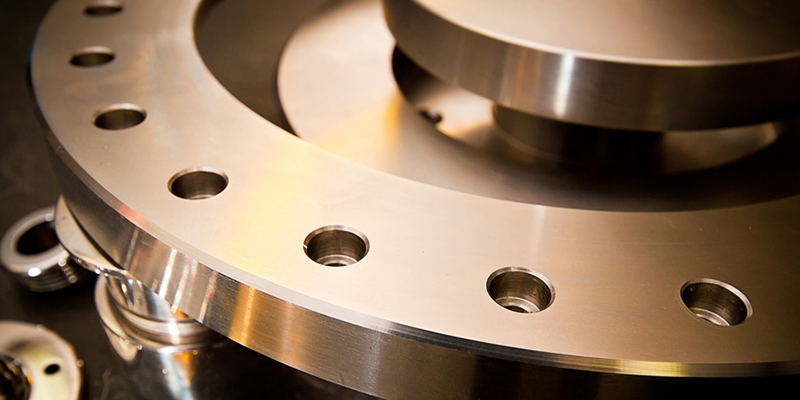

2. ALTEF (Teflon)

ALTEF (Teflon) yog ib hom kev kho deg txheej txheem siv hauv CNC machined qhov chaw. Nws sawv cev rau Aluminium Teflon Electroless Nickel Plating, thiab nws yuav tso ib txheej nyias ntawm electroless npib tsib xee rau saum npoo ntawm txhuas, ua raws li txheej ntawm Teflon.

Cov txheej txheem ALTEF yog siv los txhim kho qhov hnav tsis kam thiab txo qhov kev sib txhuam coefficient ntawm txhuas qhov chaw. Electroless npib tsib xee txheej muab ib qho nyuaj, corrosion-resistant nto uas txhim kho lub durability ntawm ib feem, thaum lub Teflon txheej txo cov coefficient ntawm kev sib txhuam ntawm ib feem thiab lwm qhov chaw, kev txhim kho ib feem ntawm zawv zawg zog.

Cov txheej txheem ALTEF ua haujlwm los ntawm thawj zaug ntxuav cov txhuas kom tshem tawm cov impurities lossis cov khoom paug. Tom qab ntawd, qhov no yog submerged nyob rau hauv ib qho kev daws teeb meem uas muaj cov tshuaj electroless npib tsib xee plating, uas tso ib txheej ntawm npib tsib xee rau saum npoo ntawm ib feem los ntawm cov txheej txheem autocatalytic. Cov nickel txheej feem ntau yog nyob ib ncig ntawm 10-20 microns tuab.

Tom ntej no, ib feem yog submerged nyob rau hauv ib tug tov uas muaj Teflon hais, uas ua raws li cov nickel txheej thiab tsim ib tug nyias txheej ntawm Teflon nyob rau saum npoo ntawm ib feem. Teflon txheej feem ntau yog nyob ib ncig ntawm 2-4 microns tuab.

Qhov tshwm sim ntawm cov txheej txheem ALTEF yog qhov hnav-tiv taus thiab tsis tshua muaj kev sib txhuam ntawm qhov txhuas, uas yog qhov zoo tagnrho rau kev siv hauv kev ua haujlwm siab thiab kev ua haujlwm siab, xws li aerospace, automotive, thiab kev kho mob kev lag luam.

3. Hmoov Txheej

Qhov no yog cov txheej txheem uas cov hmoov qhuav yog electrostatically siv rau saum npoo ntawm txhuas thiab tom qab ntawd ci los ua kom ruaj khov, zoo nkauj tiav.

4. Tshuaj Polishing

Cov txheej txheem no siv cov tshuaj los tshem tawm cov khoom me me los ntawm qhov chaw ntawm cov txhuas los ua kom zoo nkauj, ci ntsa iab.

5. Mechanical Polishing

Cov txheej txheem no suav nrog kev siv cov abrasives los tshem tawm cov khoom siv los ntawm qhov chaw ntawm txhuas los tsim kom muaj kev sib tw, ci ntsa iab.

6. Sandblasting

Cov txheej txheem no suav nrog kev siv cua txias lossis dej kom tawg cov xuab zeb lossis lwm yam khoom siv abrasive mus rau saum npoo ntawm txhuas los tsim kom muaj kev ntxhib los mos.