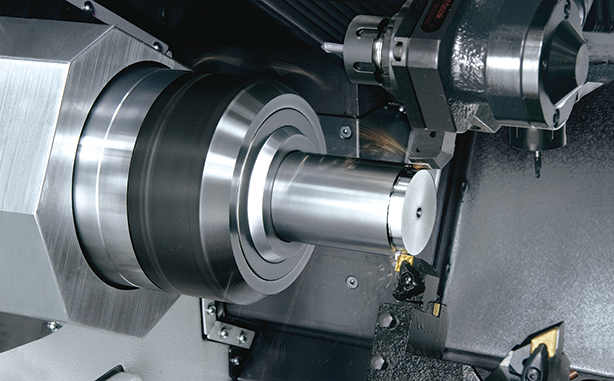

Transforming Precision Nrog CNC Hlau Raws

Dab tsi teeb tsa peb CNC hlau tig sib nrug?

1.Qhov kev engineering:Peb cov kev pab cuam CNC hlau siv los tsim cov chaw nrog kev ua kom muaj kev pab, kom txhua qhov sib luag hauv nws cov ntawv thov. Peb ua tiav qhov no los ntawm kev ua haujlwm meticming thiab qhov kev kuaj xyuas zoo thoob plaws hauv cov txheej txheem ntau lawm.

2.Versatility:Los ntawm cov me me, cov chaw zoo rau cov khoom loj, cov khoom siv nyuaj, peb lub tshuab CNC tuaj yeem ua ntau qhov ntau thiab tsawg thiab cov duab. Cov versatility no ua rau peb tus khub zoo rau kev lag luam xws li aerospace, kho tsheb, thiab ntau yam.

3. tsawv:Lub sijhawm yog nyiaj, thiab peb cov txheej txheem ntau lawm ua kom muaj kev hloov lub sijhawm sai sai uas tsis muaj kev cuam tshuam zoo. Peb cov hloov pauv tau ua haujlwm thiab cov Machinery txhua yam tso cai rau peb kom tau raws li cov hnub kawg thiab xa tawm ntawm lub sijhawm.

4.Cub-zoo daws:Peb nkag siab txog qhov tseem ceeb ntawm kev nyob hauv pob nyiaj. Peb cov kev pab cuam CNC hlau yog cov luv luv, muab koj nrog cov khoom zoo ntawm cov nqi pheej yig. Peb ua haujlwm ze nrog koj kom ua kom tsim qauv zoo thiab txo cov khoom siv pov tseg, tus nqi tsim khoom lag luam uas yuav txo qis.

Xaiv Lairun rau koj qhov kev xav tau CNC hlau txoj kev xav tau thiab paub qhov txawv qhov tseeb engineering tuaj yeem ua. Tiv tauj peb rau peb niaj hnub no los tham txog koj txoj haujlwm thiab tshawb pom tias peb tuaj yeem pab koj ua tiav koj cov hom phiaj tsim txiaj thiab kev ua tau zoo.